G Series Chassis

Mechanical pendulum bearings on the cassettes and axles from JLB 20 onwards ensure even loading of all rollers and floors. The need for vulnerable and complex hydraulic balancing is eliminated.

Half the roller width and double the number of rollers significantly facilitate steering movements and drastically reduce friction when cornering.

The significantly reduced friction also has a positive effect on the trailing axle of the JFB chassis, resulting in stable driving.

All transport chassis are ready for immediate use:

The steering unit is supplied with a ball-bearing turntable and the drawbar shown. The chassis consists of two cassettes with connecting rods as shown above.

H Series Chassis

Unprecedentedly small and lightweight transport chassis for high load capacity.

Mechanical pendulum bearings on the steering units ensure even loading of all rollers and floors.

All chassis are ready for immediate use:

The steering unit is supplied with a ball-bearing turntable and drawbar. The chassis consists of two cassettes with connecting rods.

Also available as a professional version with JUWAthan double rollers: with half the width and twice the number of rollers, steering movements are significantly easier and friction forces are drastically reduced when cornering. The significantly reduced friction also has a positive effect on the trailing axle of the JFB chassis, ensuring stable driving.

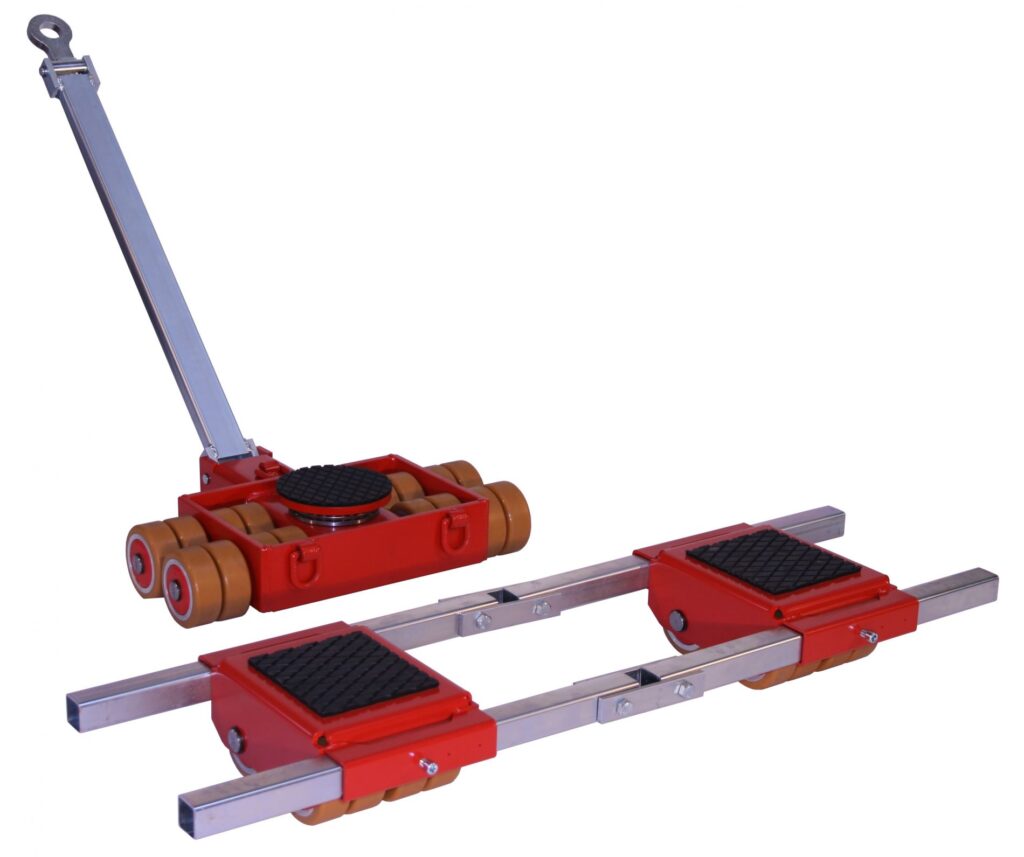

K Series Chassis

Galvanized axles, bolts, and retaining rings for optimal corrosion protection.

Equipped with optimized roller coating quality as standard.

Lighter weight with the same high load capacity thanks to improved housing design.

All transport trolleys are ready for immediate use: The steering unit is supplied with a ball-bearing turntable and the drawbar shown. The trolley consists of two cassettes with a connecting rod, as shown above. Non-marking support rollers.

The K Series drawbar is also available with a removable handle.

The removable handle is also available as a retrofit kit.

M Series Chassis

Swivel casters reduce steering effort from a standstill by up to 80%.

Ergonomic, effortless operation for the user.

Steerable driving thanks to the rigid rear axle with professional casters.

Each cassette can be used as a steering or chassis unit.

Extremely maneuverable thanks to a ball-bearing turntable with a non-slip surface.

Can be used flexibly as a steering unit, chassis unit, or tandem unit.

Can be moved 90° to the track.

Gentle on the floor, no abrasion due to the roller surface.

Low installation height, low weight.

The set includes an additional drawbar for re-steering at the rear, allowing for very tight curves.

S Series Chassis

Mechanical self-aligning bearings for the cassettes and axles (except JLB 16 S). This ensures even loading of all casters and floors.

Narrower casters (60 mm running width) significantly facilitate steering movements and drastically reduce frictional forces when cornering.

Very low installation height (125 mm) with high load capacity and low dead weight.

All transport trolleys are ready for immediate use:

The steering unit is supplied with a ball-bearing turntable and drawbar.

The trolley consists of two cassettes with connecting rods, as shown.

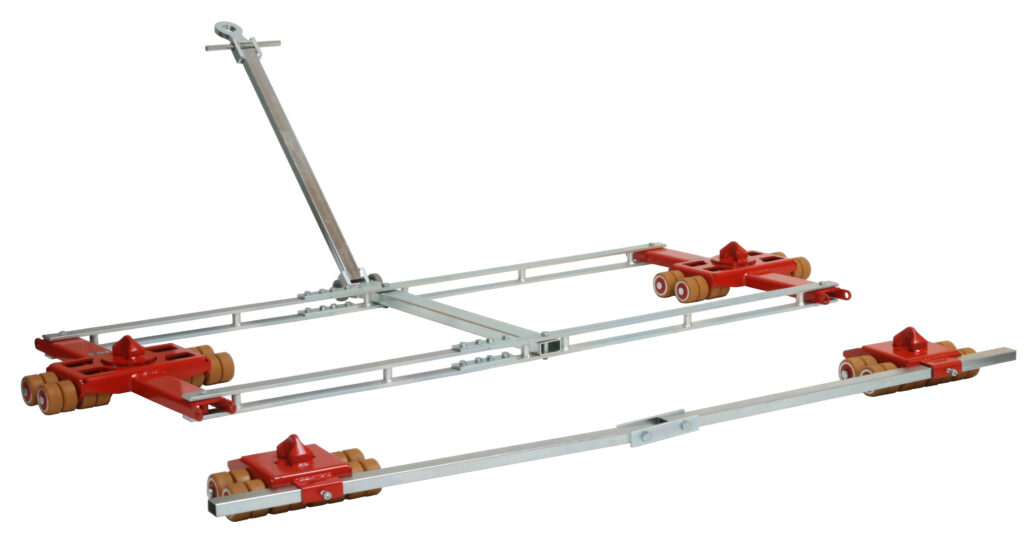

Chassis for containers

Safe transport of containers.

Containers can be moved at a low installation height.

Positive and frictional connection between trolleys and containers (Twistlock system) or only positive connection (“Weld-on Cone” system).

Suitable for all ISO containers.

The “Weld-on Cone” version includes two modified turntables or chassis cassettes with container mounts, non-lockable, and extended, two-piece tie rods (2.26 m) for ISO containers instead of the standard tie rods. The tandem steering units are supplied including a drawbar with a towing eye.

The lockable twistlock version includes two modified turntables or chassis cassettes with a twistlock system and extended, two-piece tie rods to ISO dimensions (2.26 m; non-adjustable) instead of the standard tie rods.

The tandem steering units are supplied including a drawbar with a towing eye.

Electric Trolleys

No separate tractor required.

Convenient, with battery and handy radio remote control!

Long runtime (at full load under ideal conditions) thanks to the direct-drive motor.

Short charging time.

JLA-e 5/12 G = 2.5 hours

JLA-e 15/30 G and JLA-e 25/50 H with quick charger = 1.5 hours.

Alternatively available with a small charger.

Rotates 360°.

Infinitely variable speed.

Compact external dimensions.

Batteries are interchangeable.

Suitable for the G Series (p. 32-33) and H Series (p. 36-37) trolleys.

The trolleys are not included.

Lifting available upon request.

LiFePo battery technology.

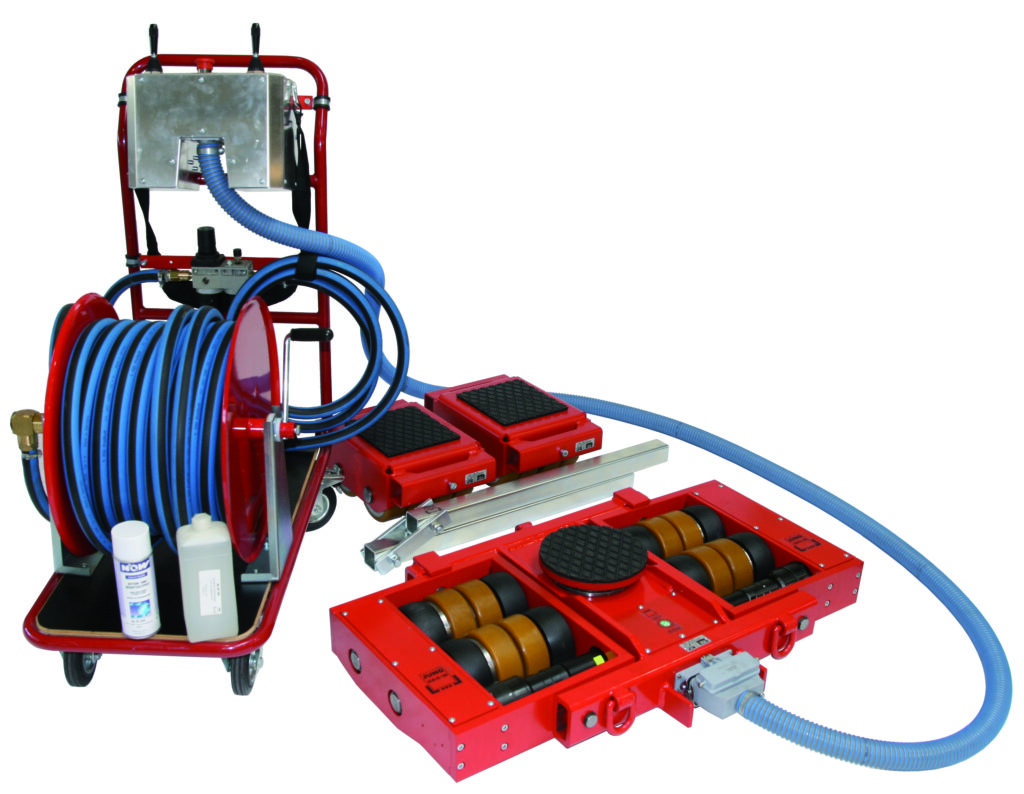

Pneumatic Trolleys

Very short setup time: connect the air hose and drive off.

No separate tractor required.

Low-maintenance drive.

All lines are detachable, allowing for compact transport.

Rotatable 360°.

No waiting time for charging.

Environmentally friendly, uses only compressed air.

Requires a standard 8 bar compressed air connection and a compressed air volume of 1500 L/min (25 L/s).

Infinitely adjustable through working pressure adjustment.

Suitable for G-series trolleys (pages 32-33).

The JLA-p 15 ⁄ 30 G item includes the powered trolley including the control unit.

Simple control via two control levers; both motors can be controlled individually.

Forward, backward, and turn on the spot with just a touch of a finger.

Higher load capacities available upon request.

Gyroscopic Trolleys

An optional connecting rod can be easily clamped onto the drawbar holder without the need for tools.

Low weight yet high load capacity.

Rotatable 360° thanks to ball-bearing swivel casters.

The installation height of the JKB 1.5 K/JKB 3 K/JKB 4 K/JKB 6 K/JKB 7.5 K gyroscopic trolleys matches K-series steering and transport trolleys. The installation height of the JKB 10 G matches G-series steering and transport trolleys.

All devices are also available as a set of two at a discounted price.

Unrivaled: The narrow width of the swivel casters on all gyroscopic trolleys reduces steering and turning resistance to a minimum.

The JKB 3 – 7.5 trolleys can be connected to the load using standard lashing straps at the designated openings.

Additionally, all chassis have central holes to allow for securing the load.

Tip: When selecting the appropriate rotary chassis, we recommend a payload of approximately 2/3 of the maximum load capacity. This provides the best compromise between payload, ergonomics, and handling of the equipment.

Drawbar and connecting rods are available as accessories.

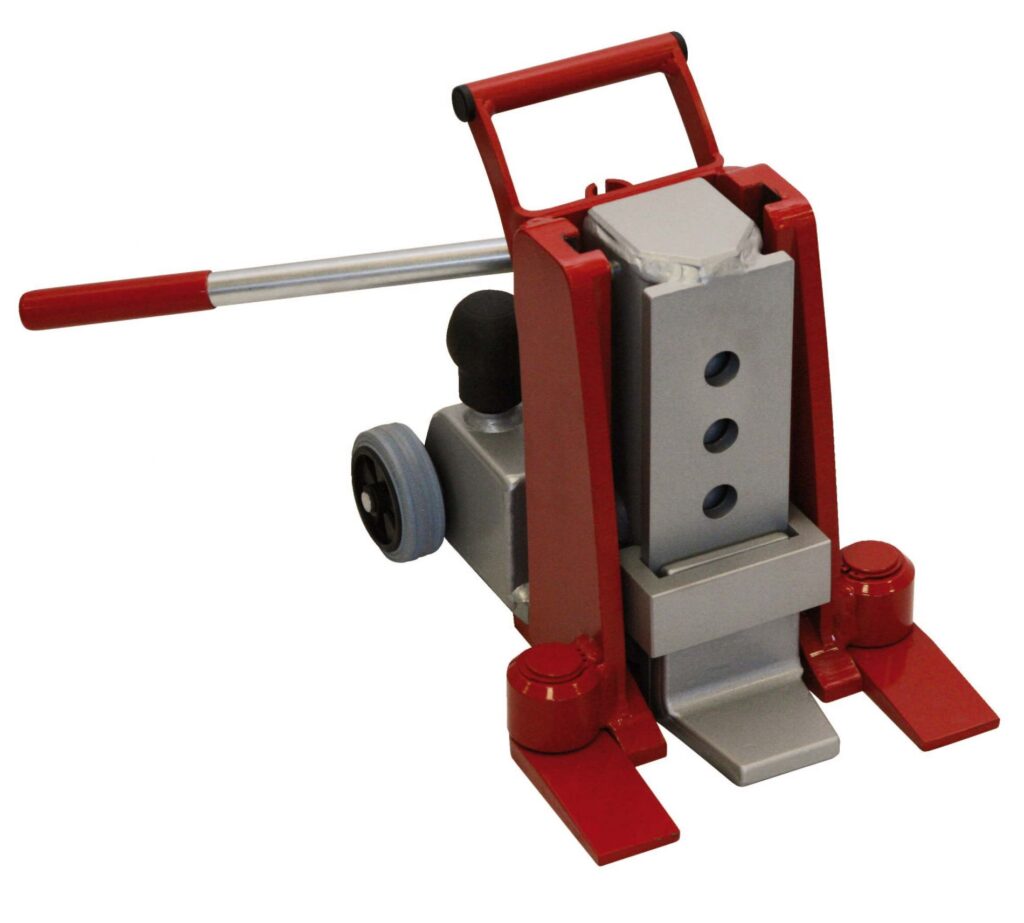

Lifting Sets

The slider can be rotated 180°, allowing the jack to be positioned either with long feet towards the load or with short feet if there is no free space under the load.

Very high lifting height:

JHS 5 with the lifting lug 250 mm, with the head plate a maximum of 585 mm.

JHS 10 with the lifting lug 260 mm, with the head plate a maximum of 610 mm.

High load capacity – up to 20 tons per set – with a low dead weight, making it ideal for use on construction sites and when frequently relocated. Can also be used horizontally for pushing.

Safe: Use with a separate pump and hoses provides a greater safety distance from the load.

Lifting Devices

New: Ergonomic and safe operation thanks to retraction by an internal tension spring on the JH 15 to JH 30 G plus EX (see Fig. 1).

Reduced friction thanks to sliding blocks, each of which can be moved within its seat. A significantly larger surface area is available for power transmission in every operating condition than with conventional devices (see Fig. 2).

The advantages include reduced wear on the guides and increased efficiency. Low maintenance costs thanks to the removable lifting unit and replaceable sliding blocks. Extremely lightweight yet high-performance thanks to high-quality materials and innovative design.

The pivoting lug ensures optimal adjustment to the load at all times. Always stable, even when raised (see Fig. 3).

Hydro Transporters

Hydro transporters are easy and very safe to handle. The two hydraulic transporter halves are clamped together with the strapping belt on the sides of the equipment or goods to be transported (cabinets, safes, machinery, boxes, etc.), creating a transport unit.

With a few pump movements on the two hydraulic lifting devices, the load is lifted and ready to move.

The two control rods keep the two large ball-bearing wheels parallel in the direction of travel at all times. This results in the lowest rolling resistance. Both hydraulic transporter halves can be transported together in a compact manner.

JHT 18 S scope of delivery: 2 transport halves, 2 tensioning straps (5 m).

JHT 30 / 38 S scope of delivery: 2 transport halves, 1 tensioning strap (5 m).

Large lifting height: 180 mm.

Didn’t find the product you were looking for? We have other products in stock! Just give us a call or send us a message.